Machine-learning wall-model large-eddy simulation accounting for isotropic roughness under local equilibrium

Rong Ma and Adrian Lozano-Duran in the ALG Lab (formerly Computational Turbulence Group) have developed a wall model for large-eddy simulation using machine-learning techniques. The model accounts for surface roughness effects on turbulent flows, and offers higher accuracy than existing models.

Authors: Rong Ma and Adrian Lozano-Duran

Citation: Journal of Fluid Mechanics, March 14, 2025

Abstract:

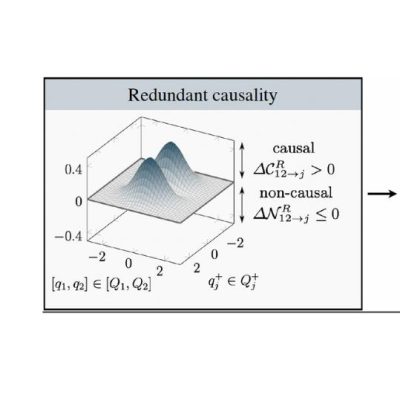

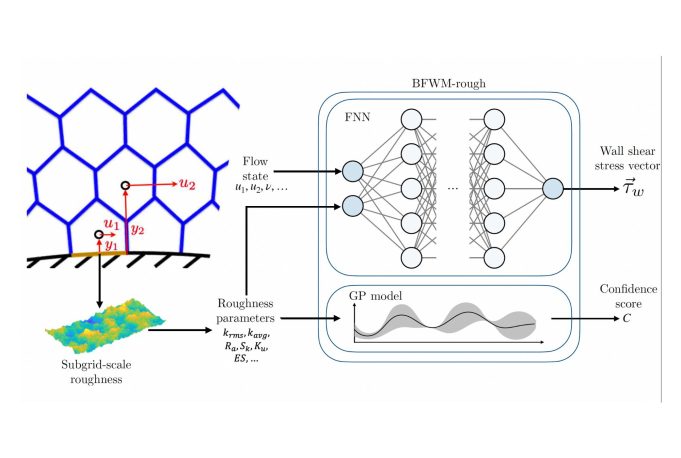

We introduce a wall model for large-eddy simulation (WMLES) applicable to rough surfaces with Gaussian and non-Gaussian distributions for both the transitionally and fully rough regimes. The model is applicable to arbitrary complex geometries where roughness elements are assumed to be underresolved, i.e. subgrid-scale roughness. The wall model is implemented using a multi-hidden-layer feedforward neural network, with the mean geometric properties of the roughness topology and near-wall flow quantities serving as input. The optimal set of non-dimensional input features is identified using information theory, selecting variables that maximize information about the output while minimizing redundancy among inputs. The model also incorporates a confidence score based on Gaussian process modelling, enabling the detection of potentially low model performance for untrained rough surfaces. The model is trained using a direct numerical simulation (DNS) roughness database comprising approximately 200 cases. The roughness geometries for the database are selected from a large repository through active learning. This approach ensures that the rough surfaces incorporated into the database are the most informative, achieving higher model performance with fewer DNS cases compared with passive learning techniques. The performance of the model is evaluated both a-priori and a-posteriori in WMLES of turbulent channel flows with rough walls.

Over 550 channel flow cases are considered, including untrained roughness geometries, roughness Reynolds numbers and grid resolutions for both transitionally and fully rough regimes. Our rough-wall model offers higher accuracy than existing models, generally predicting wall shear stress within an accuracy range of 1%–15%. The performance of the model is also assessed on a high-pressure turbine blade with two different rough surfaces. We show that the new wall model predicts the skin friction and the mean velocity deficit induced by the rough surface on the blade within 1%–10% accuracy except the region with transition or shock waves. This work extends the building-block flow wall model (BFWM) introduced by Lozano-Durán & Bae (2023. J. Fluid Mech. 963, A35) for smooth walls, expanding the BFWM framework to account for rough-wall scenarios.