Mach 3.5 compression corner control using microvortex generators

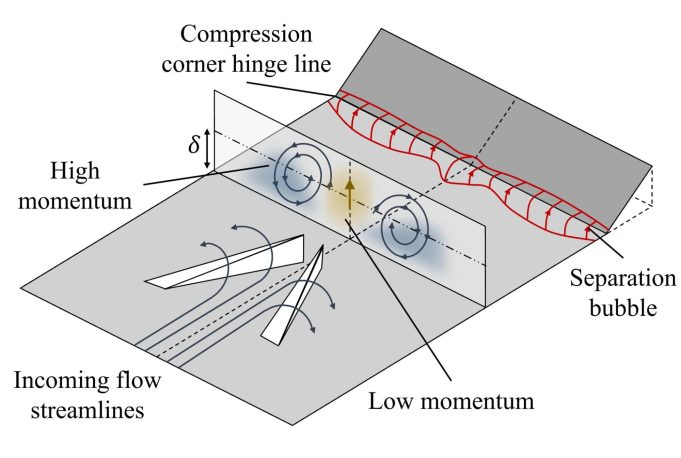

In high-speed engine inlets, shock waves interacting with the near-wall flow can have significant detrimental effects on the propulsion system. Daniel Gochenaur (Engineering Systems Lab) and co-authors help to clarify how vortex generators, a type of passive flow control device, can be used to mitigate these negative effects.

Authors: Daniel Gochenaur, Rhys Williams, Kshitij Sabnis, Holger Babinsky

Citation: AIAA Journal, March 2024

Abstract: An experimental investigation has been performed to examine the effect of vortex generators (VGs) on a compression corner flow separation. Experiments are conducted at Mach 3.5 along a 23° compression corner with turbulent inflow boundary-layer and Reynolds number 27e4 based on the 6.2-mm boundary-layer thickness. Micro-ramp, standard ramped-vane, and inverted ramped-vane VGs all cause the separation line to ripple and become more three-dimensional, but none eliminate it altogether. Vane-type VGs produce a stronger control effect than micro-ramps. Inverted vanes tend to generate large areas of near-wall low-momentum flow that locally increase separation length, making standard vane configurations more effective at reducing separation size. Velocimetry measurements show that the VG-induced vortices remain coherent and capable of exchanging momentum within the boundary-layer, even downstream of the interaction. Enhanced flow three-dimensionality causes an intensification of areas of increased and decreased momentum downstream of reattachment, resulting in significant flow distortion. Increased near-wall turbulent fluctuations are observed upstream of the interaction in areas where separation length is reduced. These findings are used to propose a mechanism of VG control, highlighting the role of VGs in enhancing mixing in the separated shear layer, leading to earlier reattachment and an overall reduction in separation length.