From Sustainability to Stealth: Advanced Aerogel-Inspired Engineering

To tackle pressing environmental challenges, our team has pioneered scalable, cost-effective technologies that recycle almost all common wastes—plastic, agricultural, metallic, and rubber—into high-value aerogel-inspired materials (AIMs) for diverse industrial, environmental, and defense applications. Unlike conventional batch aerogel methods, our sustainable continuous process achieves mass production with drastic energy savings and ultra-low emissions (0.1 kg CO₂/m² AIM). These eco-AIMs are versatile, enabling CO₂ capture, food preservation, wastewater treatment, oil spill cleanup, cultured meat growth, medical and thermal insulation, and defense applications.

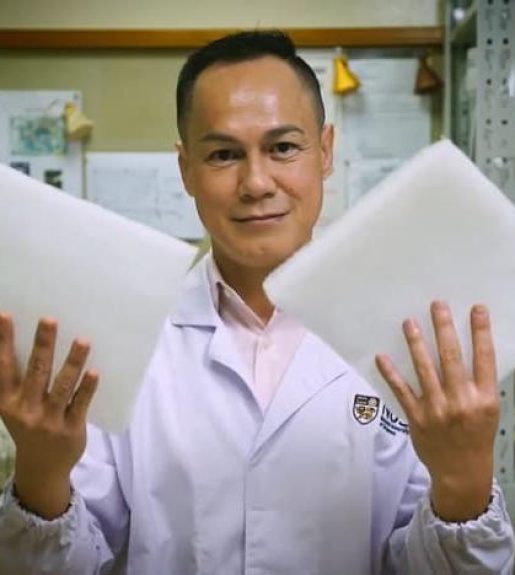

To overcome the limitations of current electromagnetic wave absorption (EWA) materials, we developed lightweight, porous hybrid AIM sheets using recycled plastic fibers and commercial CNTs via a modified needle-punched nonwoven and thermal-bonding process. Operating continuously at ~1 m/min without toxic solvents, our TRL7 pilot system produces flexible, durable, low-cost sheets with exceptional EMW absorption (90–99.99% over 1–12 GHz)—ideal for stealth and EMI shielding.

These breakthrough sustainable technologies have earned multiple global innovation awards and attracted strong international interests including from the USA. They have been commercialized in Singapore and Vietnam.